Manufacturing Lifecycle

A typical Manufacturing lifecycle is shown below. At Just Electronics, we can perform the entire lifecycle on your behalf, or engage in only the processes you require.

Design

Many of our customers provide their own design, gerber files, and even screens, but if you need help with any of this, read up about our design services. After we have signed a non-disclosure-agreement with yourselves, you provide the design and parts list to us to provide a quote.

Prototype

New designs are usually prototyped before large quantities are ordered. We will generally build a one-off of a new product for you to test and inspect before you authorize a larger batch. To read about prototypeing, you can view your prototyping page.

Quote

Depending on whether or not you would prefer to supply your own parts - in part or completely - we go ahead and create a quote for the work that you require of us. Every quote is customized to your exact needs, and can include or exclude any of the services we provide. If you would like to discuss a quote with us, please conatct us. You can find contact information on our contact page.

Order

After acceptance of our quote, you can place your order with us, and the standard lead time would apply. For urgent jobs, an additional fee may be requested as we would need to staff up to cover this necessity. We will always discuss this with you prior to proceeding, so there is no hidden costs at any time.

Procurement

Assuming you have not provided your own parts, we will then procure the items needed for your job. You can read up about our procurement process and services on our You can find contact information on our procurement page.

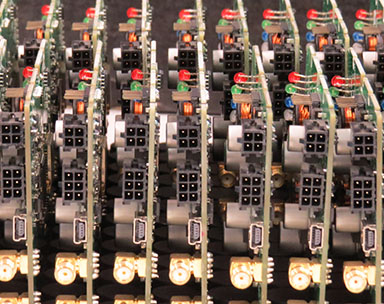

Manufacture

We use a partner to create the circuit boards on which we place the components. The parts are placed either by hand or machine on the circuit boads, and then either manually soldered and/or flow soldered into place using our flow soldering oven.

View our pick and place machine in the video below

To read more about our PCB Assembly, visit the page dedicated to it.

Inspection

All PCB's are inspected to ensure that there are no easily identifiable faults or incorrectly placed components. Inspection is done manually or via an automated optical scanner which compares finished products with an existing working product

Test

We will follow your testing process, whatever it might be. We are also happy to test against test rigs which you would provide to us, so that the manufactured parts pass your very own testing procedures. We can also provide calibration (where required) when performing the testing.

Rework

In cases where inspection finds a problem and a repair is needed, the product goes to our rework bench to be corrected. The dedicated test, inspection and rework benches are very close to each other to ensure fast processing and less risk of misplacing the item in the workshop.

Box Build

If you need us to assemble your PCB into a box, frame or enclosure so that it becomes a fully fleged product, this is one of our other major services we offer. It is known as Box Build and you can read about this on our box builds page

Final Test/Inspection

If we've done a box build, we will do final test and inspection as required by your manufacturing preferences.

Shipping

Final products can be shipped back to you or even directly to end customers - meaning that we will handle the distribution for you!

Billing

Ordinarily, we will bill after shipping the items. If payment is required up front, it is usually for unusual circumstances but we will advise this before accepting the order.